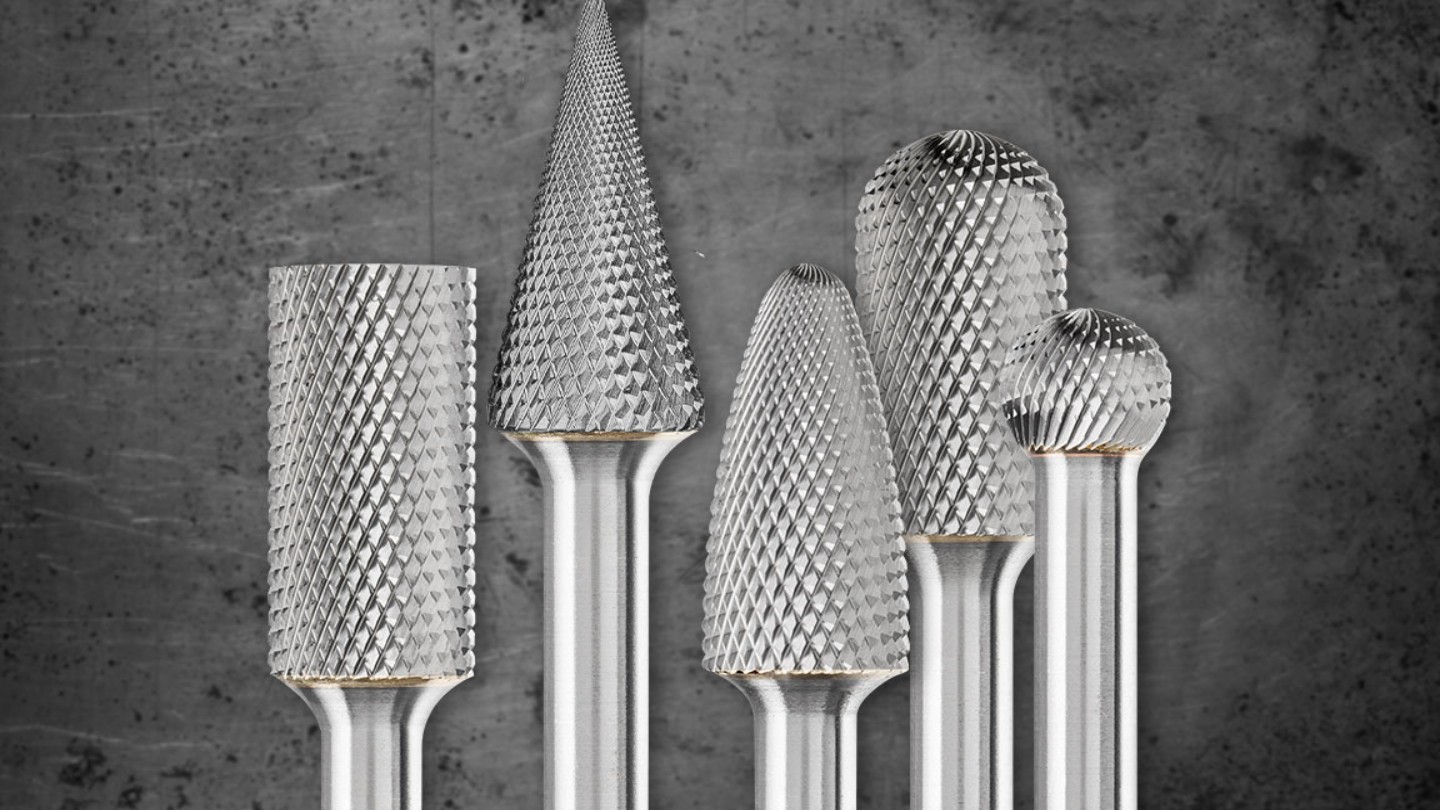

TC burrs - MICRO cut

Tungsten carbide burrs with the MICRO cut are specifically designed for finishing and are used in areas in which mounted grinding points are usually used. They offer a higher stock removal rate and produce a high surface quality, particularly compared with conventionally milled surfaces.

They also operate with low vibration and little noise. They maintain their geometry over their entire tool life, and are well suited to manual and machine applications. Almost all materials up to a hardness of 68 HRC can be machined.

Advantages:

- High surface quality.

- Unlike with mounted grinding points, there is no change in geometry due to wear and tear.

- Work on almost all materials up to 68 HRC.

- Reduced wear on the tool drive due to impact-free work without chatter marks, thanks to the high concentricity.

Materials that can be worked:

- Steel and cast steel

- Stainless steel (INOX)

- Non-ferrous metals

- Cast iron

Applications:

- Finishing

- Very fine cleaning work

- Corrections in tool and mould construction

- Sharpening cutting tools

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot applications

- Machine tools

Recommendations for use:

- If possible, use the tools on powerful drives with elastically mounted spindles to avoid vibration.

- For the cost-effective use of burrs, work with higher rotational/cutting speeds.

- Power recommendation for tool drives:

- Shank diameter of 3 mm: 75 to 300 watts

- Shank diameter of 6 mm: from 300 watts

- Please observe the rotational speed recommendations.