Recommendations for use when working on stainless steel (INOX)

In this article we have compiled a list of important considerations that are essential to bear in mind when working on stainless steel (INOX).

What is the most cost-efficient way of working on stainless steel (INOX)?

Stainless steel (INOX) is a very tough material, so the drive you use should be as powerful as possible.

The advantage of flexible shaft drive systems is that you can use a very small, lightweight handpiece with a high performance.

As a general rule, you need to use a speed-adjustable drive to be able to maintain the optimum rotational speed ranges and for the application to be as cost-efficient as possible.

How do you avoid damaging the workpiece?

The following advice should help you to protect the surface of the workpiece against damage and contamination:

- Use clamping tools (vices, screw clamps, etc.) that have protective caps (e.g. made from plastic or aluminium).

- Wear cotton gloves whenever possible. Grease and salt from the sweat on your hands can prevent or hinder the formation of the passive layer.

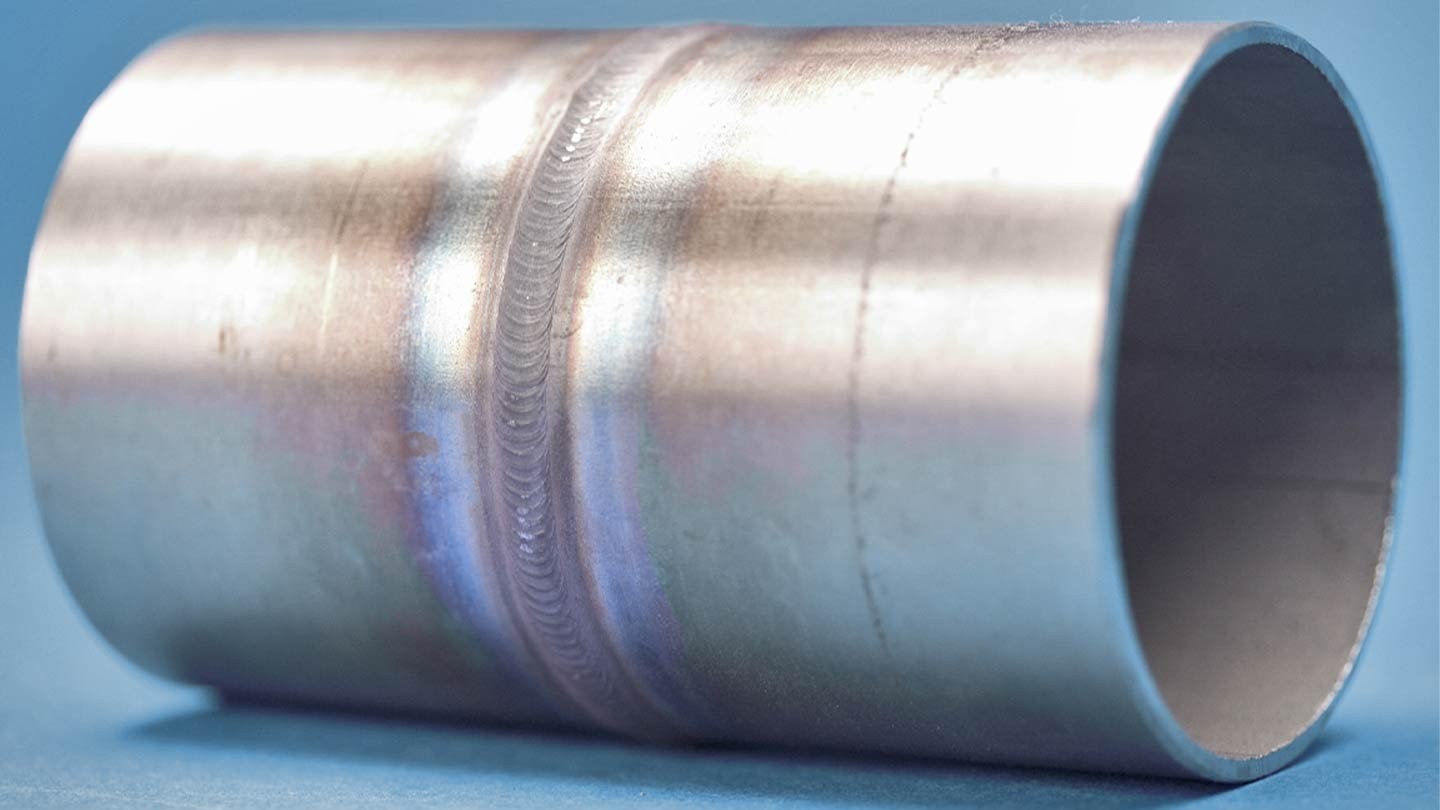

How can you prevent heat discolouration?

Stainless steel (INOX) has a very low heat conductivity. If a stainless steel workpiece is subjected to high thermal stress during application, it could take on a blue discolouration. This heat discolouration is both unsightly and creates the need for costly and time-intensive reworking. Heat discolouration and oxidation due to high heat production also increases the risk of corrosion.

The tools developed by PFERD TOOLS that have the designations INOX, COOL or FREEZE provide a solution: they prevent heat discolouration in the material due to their low heat production. You should also observe the following recommendations for use in order to prevent damage due to overheating:

- Work with as low a contact pressure as possible and use oscillating movements to prevent heat discolouration and distortions due to overheating.

- Use low cutting speeds, and cool the workpiece during the machining process if possible.

- Make sure that chips are being evacuated as efficiently as possible. Preferably use rough abrasive grit, and cool the tool during the machining process if possible.

What can you do against corrosion?

When iron and steel oxidize in the presence of water (e.g. in the atmosphere, in water and in the ground), this can result in corrosion and the formation of rust. To reduce the risk of materials made from stainless steel (INOX) corroding,

- use a passivation agent if possible. By applying a passivation agent, the workpiece will have a protective passive layer within minutes.

- Do not store workpieces you have finished processing in the same place as corroded workpieces.