Why triangles equal smooth results

Press release - 04.10.2024

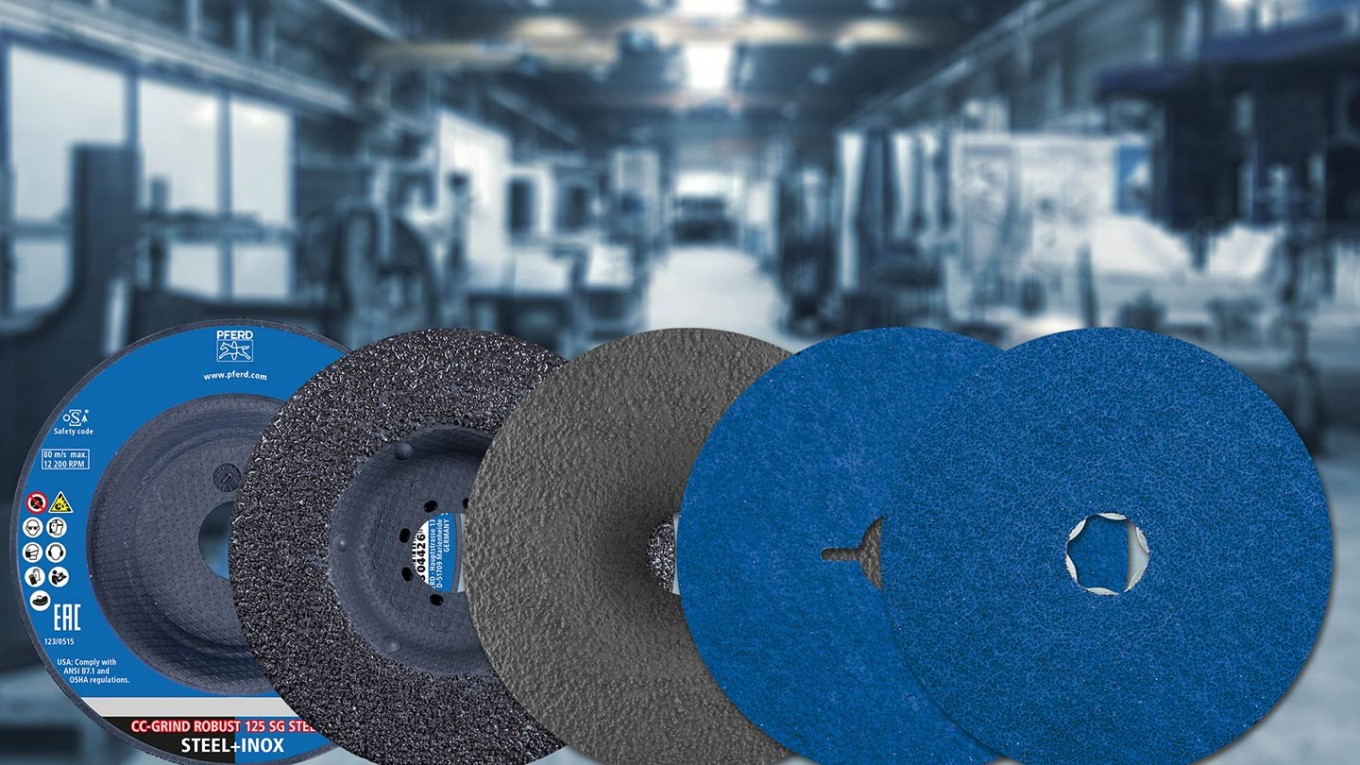

With VICTOGRAIN, PFERD presents a triangular abrasive grain that offers an exceptionally high level of abrasive performance and multiple benefits for users

When machining surfaces, precise, efficient grinding processes are essential in order to achieve high-quality results. Yet many conventional abrasives reach their limits, particularly when it comes to the combination of high stock removal rate and long tool life. Workers are also faced with the problem of increased heat build-up during intensive grinding processes. This can lead to changes in the material and defective surfaces. The innovative VICTOGRAIN abrasive grain from PFERD tackles exactly these problems.

Simply better: maximum abrasive performance thanks to VICTOGRAIN

VICTOGRAIN products from PFERD feature a triangular, precision-formed abrasive grain that achieves a uniquely high level of abrasive performance. The VICTOGRAIN abrasive grain triangles are identical in shape and size and their cutting edges are applied to the workpiece at the optimum angle, meaning the grain needs very little energy to penetrate the workpiece. This creates a highly positive impression among users. A long tool life, the ability to make progress quickly and the fact that only a small amount of heat is transferred to the workpiece mean users benefit from an exceptionally efficient machining process. “VICTOGRAIN outperforms other, established solutions by up to 30% – in terms of stock removal on steel, for example – with a consistently high degree of aggressiveness. In addition to grit size 36, VICTOGRAIN is also available in sizes 60 and 80, enabling the products to be used in an even greater range of applications,” says Ralf Heimann, product manager at PFERD. It performs impressively in use, he adds.

How VICTOGRAIN works

The VICTOGRAIN abrasive grain triangles are fixed to the substrate on one of their sides. Compared with conventional abrasive grains that tend to be fixed at points, the long edges of the triangles mean they are securely fixed in place and, together with their slim design, offer an extremely large chip space. This and the improved chip removal properties help to speed up the machining process even further. In addition, the structure of the VICTOGRAIN abrasive grain means only a very small amount of the crystal inside the triangle breaks off, resulting in optimum wear characteristics and long tool life.